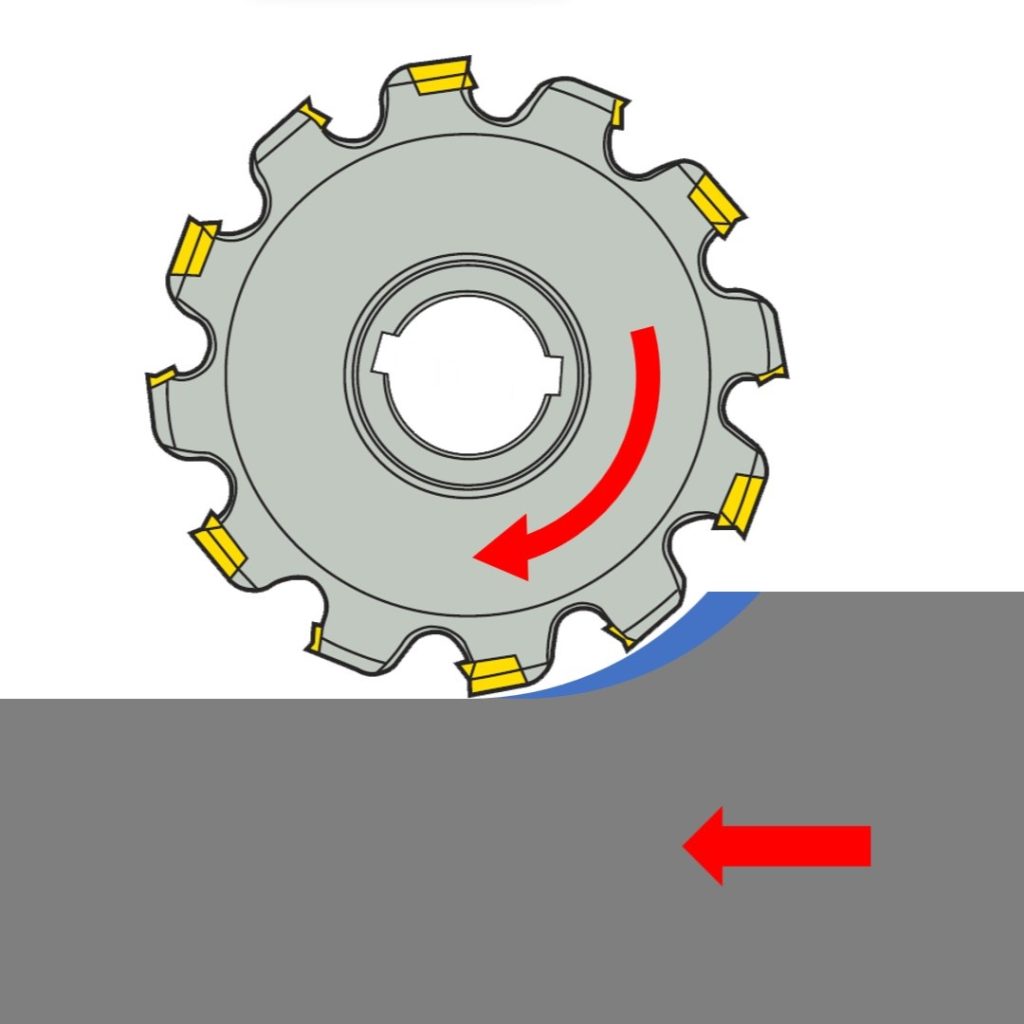

Climb Milling

Climb milling refers to the cutting direction of the tool that aligns with the feed direction of the workpiece.

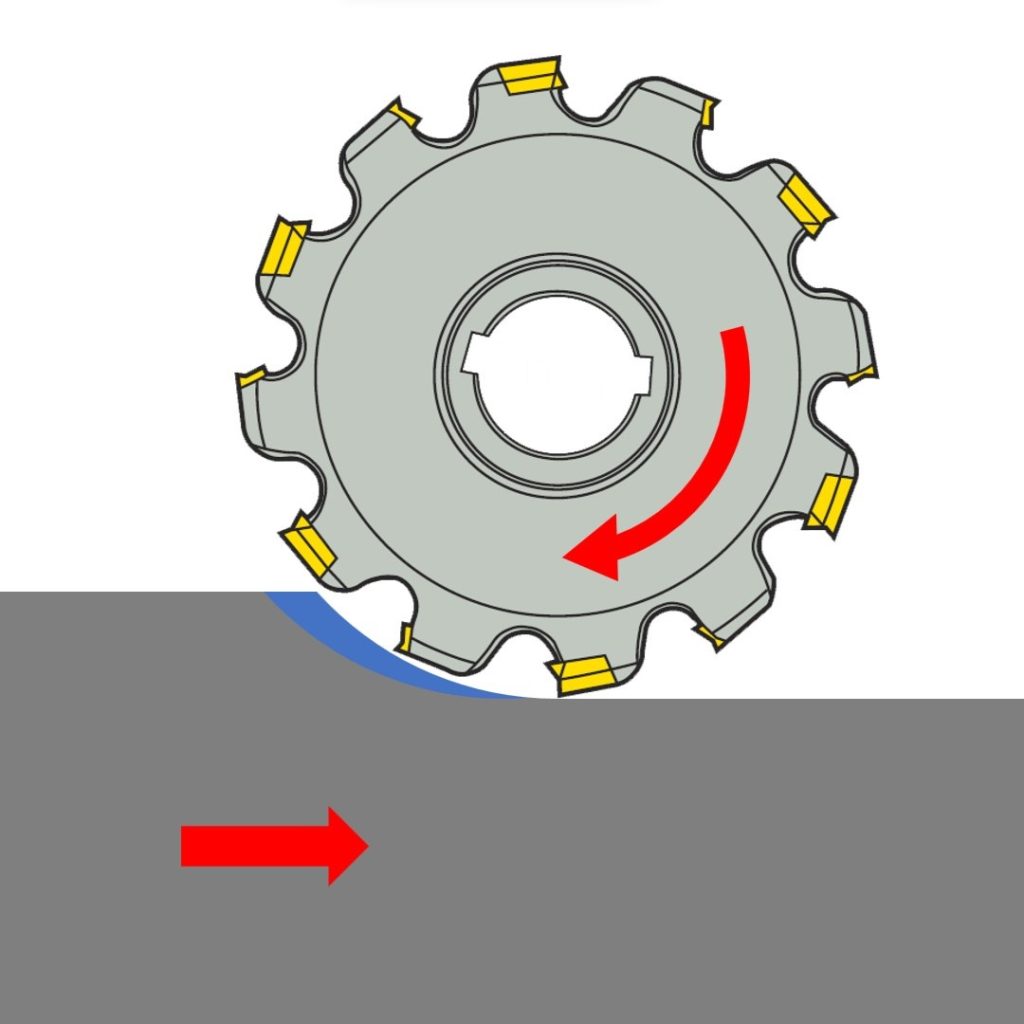

Conventional Milling

Conventional milling refers to the cutting direction of the tool that is opposite to the feed direction of the workpiece.

In a conventional milling machine, there is a driving clearance in the leadscrew-nut mechanism that drives the workpiece feed motion. Climb milling, where the cutting forces are in the same direction as the feed direction, cannot eliminate the driving clearance due to varying cutting forces. As a result, the cutting process becomes highly unstable. On the other hand, conventional milling, where the cutting forces are in the opposite direction to the feed direction, can eliminate the driving clearance. Therefore, for traditional milling, it is generally recommended to use conventional milling.

Choosing between climb milling and conventional milling is no longer a concern in modern CNC machine tools due to the resolution of the driving clearance issue.

In terms of cutting characteristics, the fundamental difference between climb milling and conventional milling is as follows:

In climb milling,

the chips change from thick to thin.

In conventional milling,

the chips change from thin to thick.

During conventional milling, when the cutting edge of the tool enters the workpiece material, it undergoes friction, then compression, and finally tearing on the already machined surface. This process generates more heat, promotes work hardening, deteriorates surface roughness, increases cutting power, reduces tool life, and is unfavorable for machining.

Therefore, in modern machine tools, climb milling is the preferred machining method.

However, even on modern machine tools, there are situations where conventional milling has its advantages. For example, when milling thin-walled top surfaces, conventional milling is suitable. In thin-walled top surface milling, climb milling with thicker chip entry can cause impact effects on the thin-walled top, leading to workpiece vibration. Conventional milling can help alleviate vibration in such cases.