Grooving Of Aerospace Spool

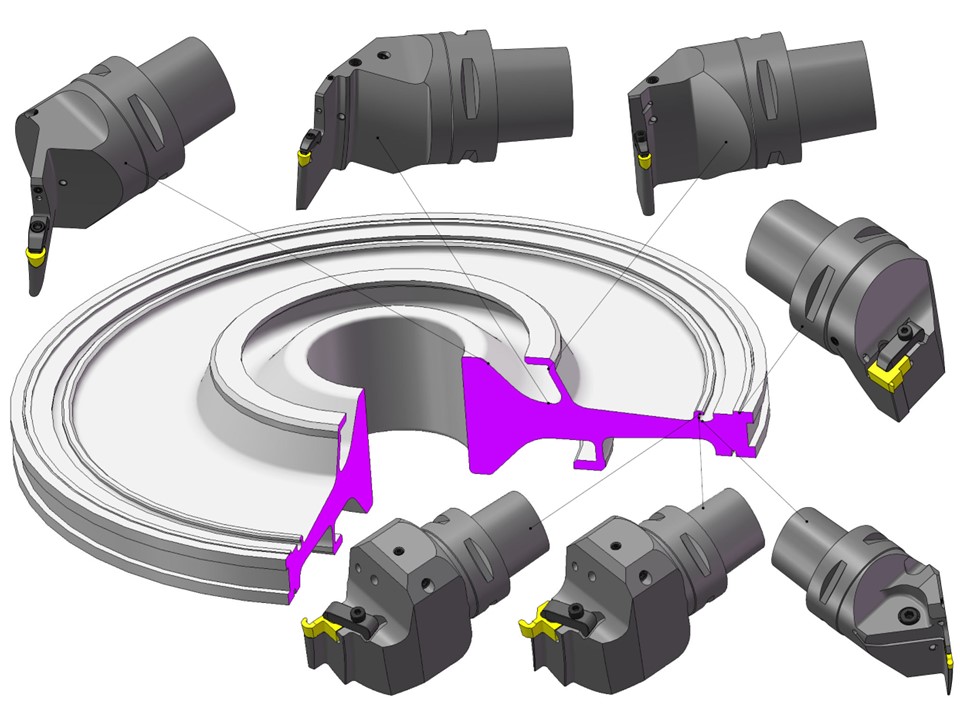

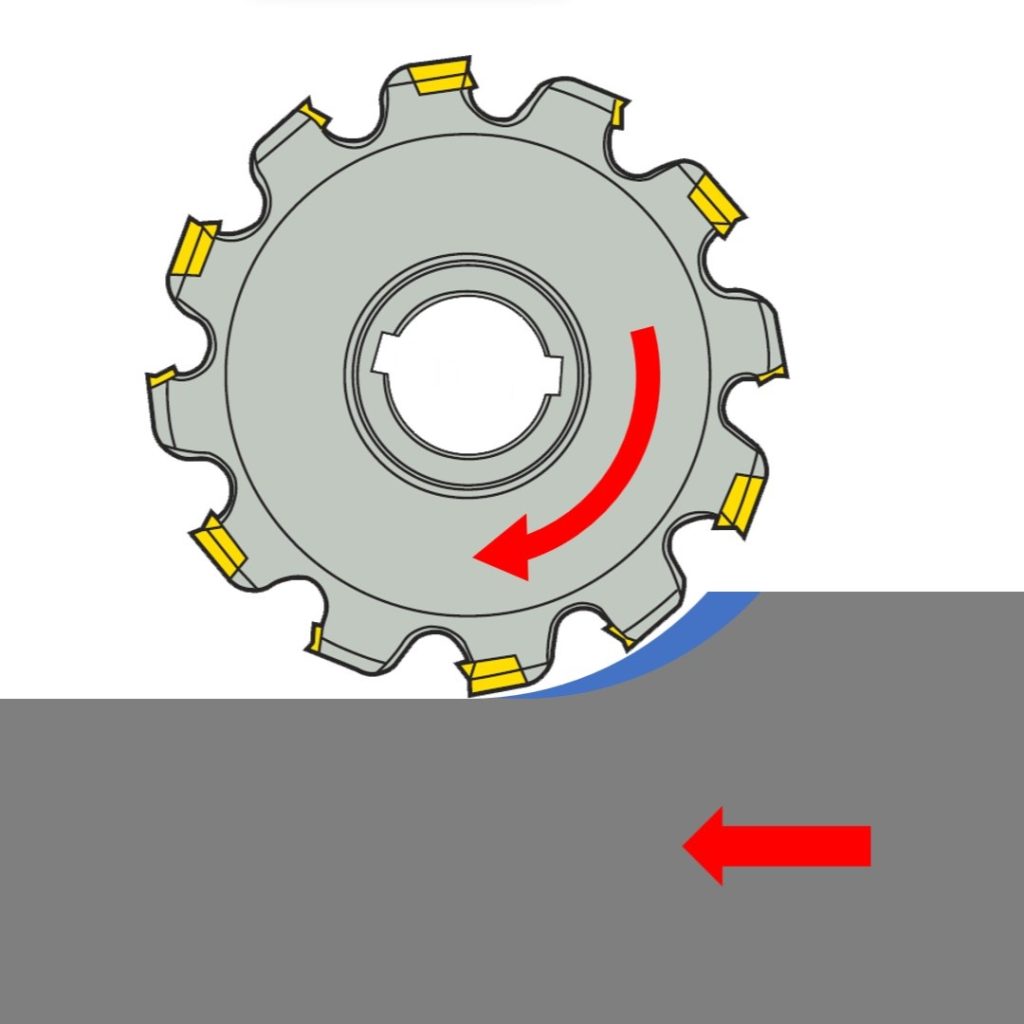

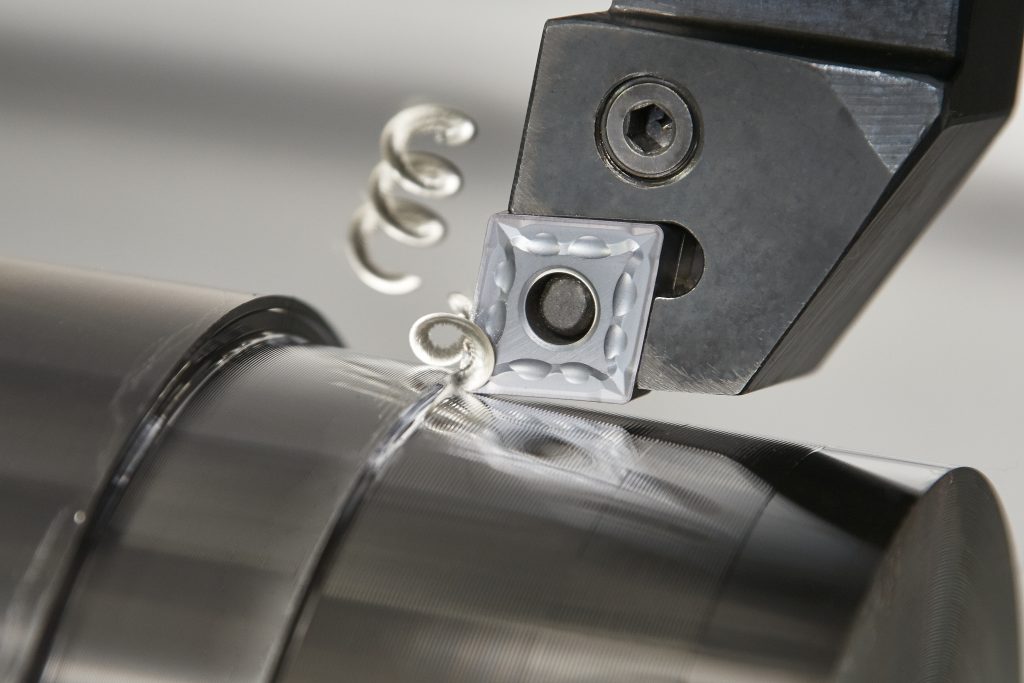

In the aerospace industry, the precision machining of components is crucial for ensuring the safety and performance of aircraft. One such important component is the aerospace spool. Grooving of aerospace spool is a specialized process that requires a high degree of accuracy and expertise. Challenges: Method: Conclusion:The grooving of aerospace spools is a complex and […]

Grooving Of Aerospace Spool Read More »