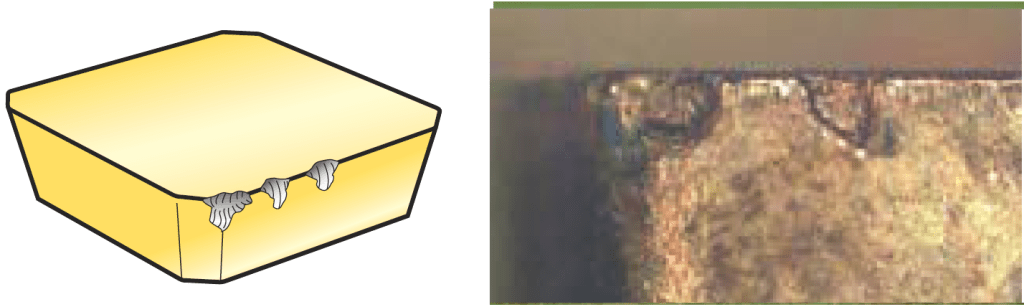

It refers to small fractures that occur on the primary cutting edge, including the cutting edge tip. In the initial stages, these fractures may not be visible to the naked eye and require magnification for observation. One can use a fingernail to lightly scrape the cutting edge and feel the distinct sensation of chipped edges.

In general, when chipping occurs on a tool, it can still be used, but chipping will reduce the tool’s lifespan.

Chipping on the cutting edge is mainly caused by vibrations in the cutting system and high adhesion of the workpiece material.

Cutting system vibrations:

In most cases, the entire cutting system experiences vibrations. When the cutting edge encounters hard spots in the workpiece material, it leads to small chipped areas.

The cutting system includes the tool, machine tool, fixture, and workpiece.

For example, damaged machine tool bearings, worn-out spindle, excessive tool overhang, thin-walled workpieces, intermittent cutting methods, etc., all contribute to poor system rigidity.

Highly adhesive workpiece material:

The workpiece material easily generates tensile stress on the cutting edge during the cutting process, leading to chipping.

Hard spots within the workpiece material:

High-hardness inclusions within the workpiece material cause localized pressure concentration, resulting in chipping of the cutting edge.

Improvement

Improving the rigidity of the cutting system:

Eliminating or reducing the occurrence of vibrations in the cutting system.

Specific measures include improving the rigidity of workpiece clamping, reducing tool overhang, increasing the diameter of the tool shank, using anti-vibration tool holders, and other methods.

Choosing tool materials with better toughness:

Enhancing the toughness of the cutting edge material.

Selecting chip breaker designs with higher cutting edge strength:

Increasing the cutting edge’s resistance to impact.

Choosing blades with higher resistance to edge chipping:

Increasing the cutting edge’s resistance to impact.

Reducing the feed rate:

Effectively reducing the load on the cutting edge.

Moderately increasing cutting speed or discontinuing the use of coolant:

Raising the temperature in the cutting area can reduce material adhesion. At the same time, the resistance to edge chipping can also improve with higher temperatures.

Improving the impact during tool entry and exit:

In certain cutting conditions, the cutting edge experiences significant impact during entry and exit. Adjusting the corresponding angles or reducing cutting parameters during entry and exit (especially the feed rate) can help mitigate this.

Choosing climb milling for milling operations:

When milling, especially for narrow edge milling or on older machines with clearance in the lead screw, using climb milling can effectively reduce cutting vibrations and improve resistance to edge chipping.