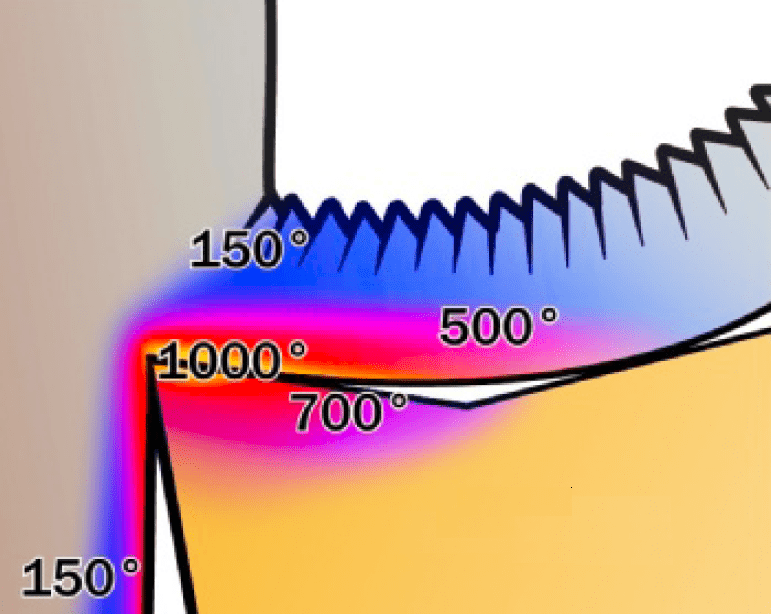

The area where crater wear occurs is the region on the face of the cutting tool where the chips come into contact. This is the hottest region during the cutting process and is subjected to high-pressure mechanical friction from the chips against the face of the tool.

Therefore, crater wear on the face of the tool is the result of combined chemical and electrochemical wear, diffusion wear, and abrasive wear.

Crater wear occurs on the face of the tool and generally does not come into contact with the cutting edge, but in some cases, it may come into contact with the cutting edge when cutting certain materials that produce short chips.

When crater wear occurs, the contact between the chips and the tool changes, leading to a decrease in edge strength, an increase in the cutting rake angle, and a slight reduction in cutting force.

Severe crater wear can easily result in edge chipping or even tool breakage.

Compression Friction from Chip Contact with the Face of the Tool

This phenomenon is more likely to occur in turning processes, where the chips continuously exert pressure and friction against the face of the tool.

The heat from the workpiece chips causes the decomposition of tungsten carbide particles in the tool’s cemented carbide material, with carbon elements diffusing into the chips. In the high-temperature and high-pressure environment, the chips continuously remove the tool’s cemented carbide material, gradually resulting in crater wear.

Improvement

Choose tool materials with better red hardness:

Improve the wear resistance of the tool at high temperatures.

Select a more suitable chip breaker design:

Improve the contact condition between the chips and the face of the tool.

Choose coatings with better high-temperature performance:

Prevent or slow down the occurrence of chips carrying away elements from the cemented carbide material.

Reduce cutting speed:

Lower the temperature in the cutting zone.

Adjust the feed rate:

Obtain the appropriate chip thickness.

Ensure adequate cooling supply:

Note that this wear area is the most challenging for coolant to reach.