Plastic deformation mainly occurs due to excessive cutting heat. Thermal overloading. It is particularly prone to occur in cutting processes with high cutting parameters and poor thermal conductivity.

High Cutting Parameters:

High cutting speed, feed rate, and cutting depth, all of which are closely related to the cutting load.

Poor Thermal Conductivity:

Materials with low thermal conductivity, small volumes of the tool and workpiece, and a relatively small and confined cutting area can cause the accumulation of cutting heat in the cutting zone.

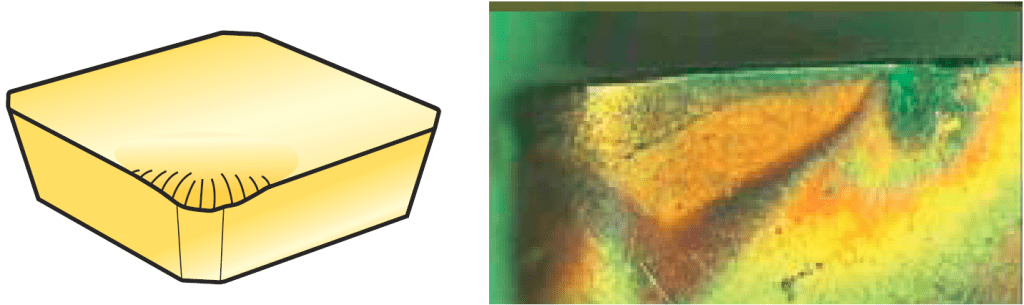

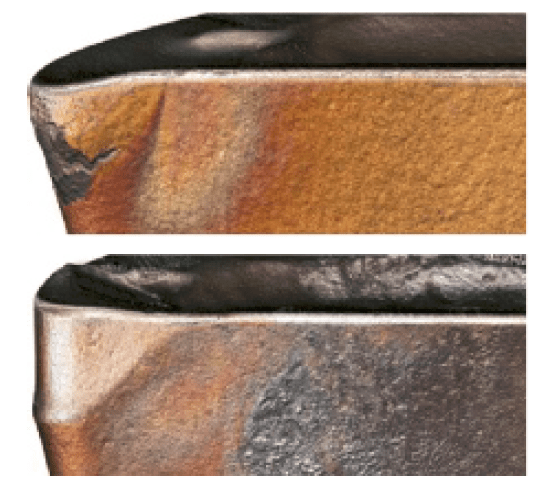

During plastic deformation, the cutting edge not only collapses but also forms indentations.

The tool may deform, but there is no material loss.

The high temperature in the cutting zone causes thermal overload, resulting in the softening of the binder phase (cobalt Co) in the tool’s cemented carbide material. Under the influence of high cutting forces, the cutting edge of the tool undergoes partial or complete plastic deformation, eventually leading to fracture or irregular wear on the rake face.

In the early stages, when it is difficult to observe with the naked eye, the new and used tool can be stacked together, and the amount of transmitted light can be observed to make a judgment.

Plastic deformation-induced wear on the rake face generally exhibits an irregular shape in the wear zone, which differs from normal rake face wear. The dimensional accuracy of the workpiece will also quickly change as a result.

Improvement

Choose tool materials with better red hardness:

Ensure that the tool maintains a certain edge strength at high temperatures.

Reduce cutting speed and feed rate:

Decrease the cutting load on the tool’s cutting edge.

Improve cooling supply:

Effectively lower the temperature in the cutting zone.

Select larger-sized tools:

Improve the efficiency of heat transfer from the tool’s cutting edge to the tool body.