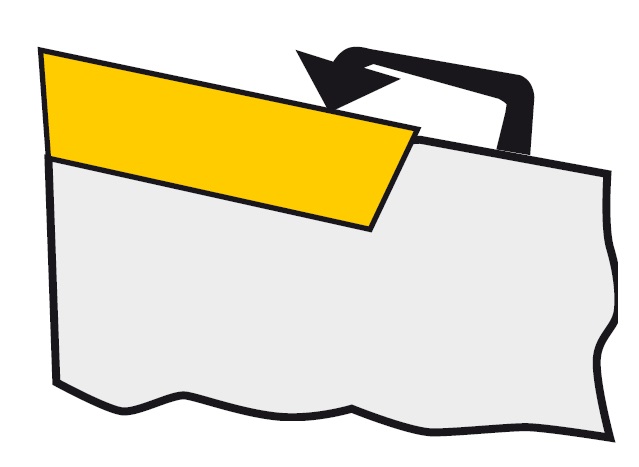

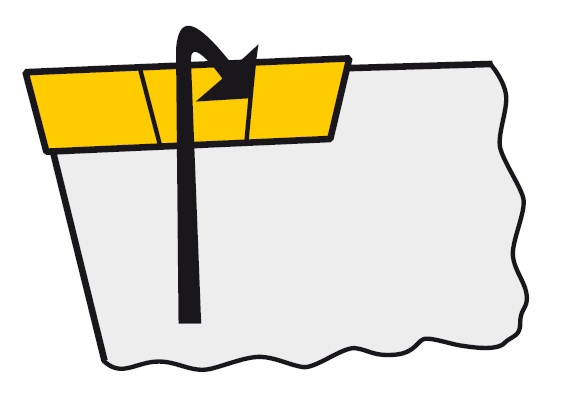

① Insert clamping

C

clamp on top of insert

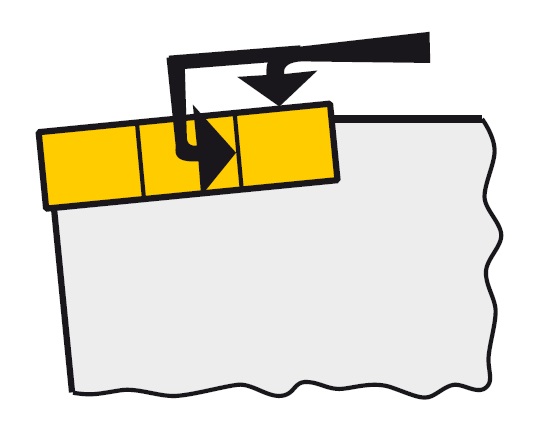

D

clamp on top of insert and into hole

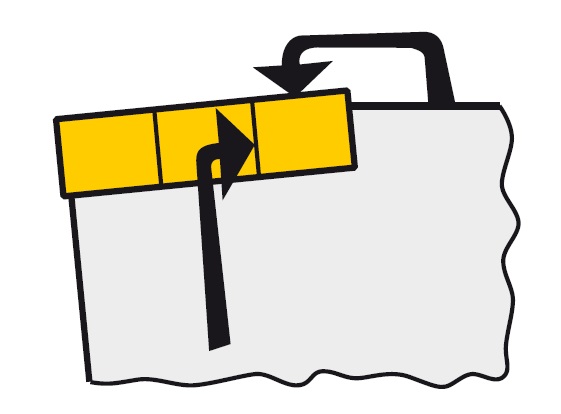

M

top and through hole clamping

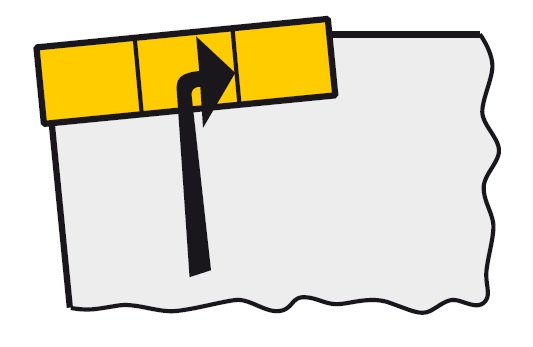

P

clamp with pin through hole

S

clamp with screw through hole

W – wedge clamping N – clamp into notch of insert

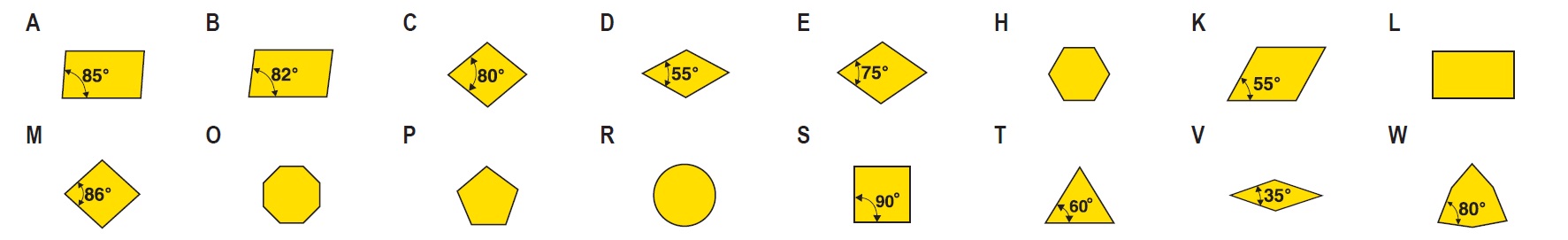

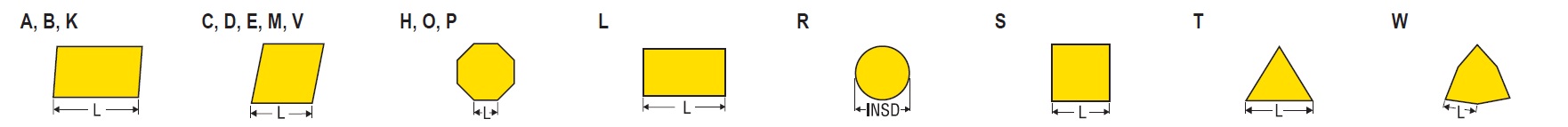

② Insert shape

X – Special shapes Z – Special shapes

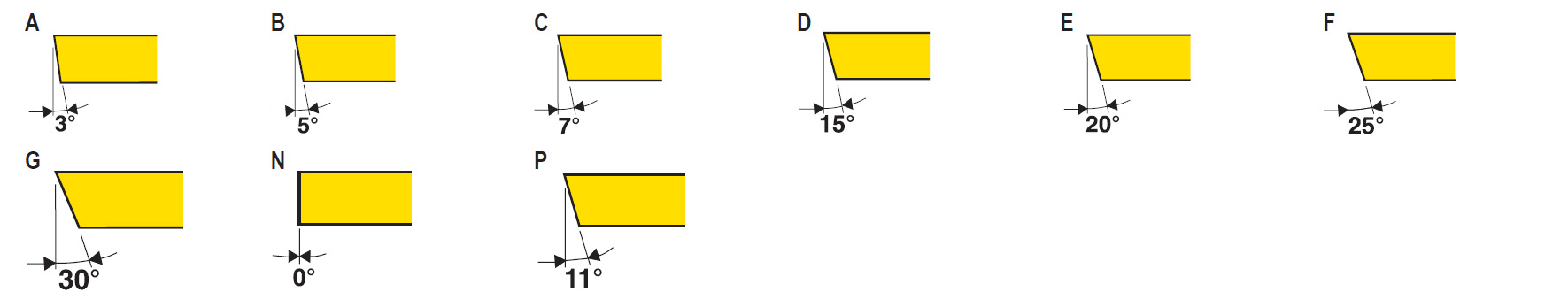

③ Tool type (approach angle)

X – Approach angles not specified in the standard.

Special information required.

④ Insert normal clearance angle

O – Special shapes

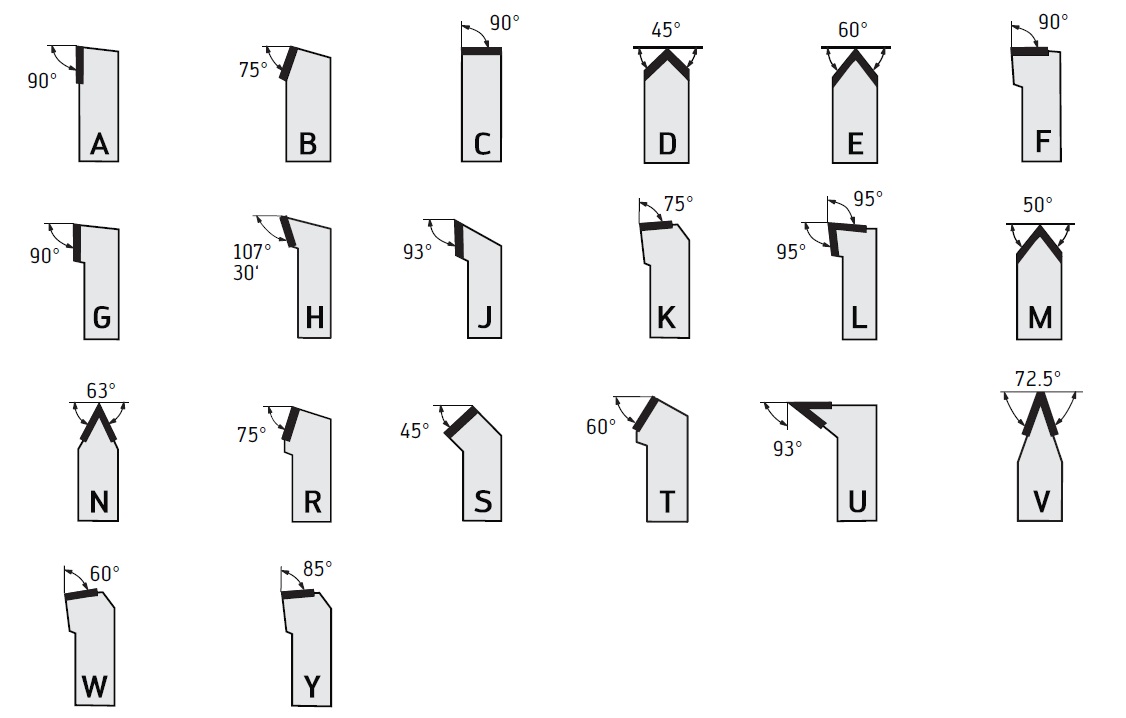

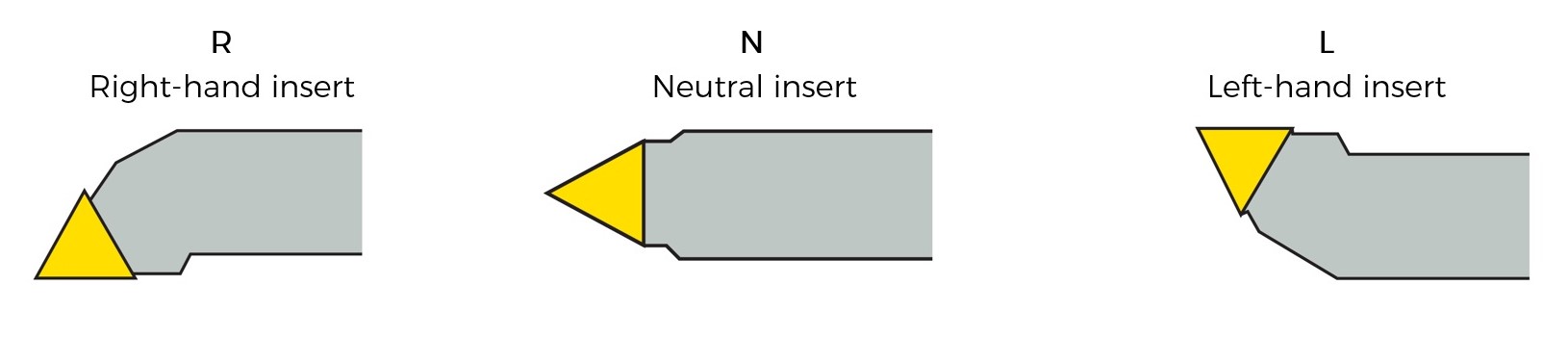

⑤ Cutting direction

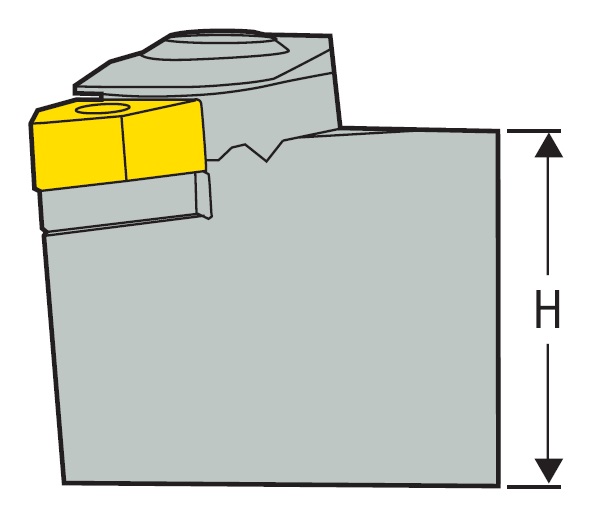

⑥ Shank hight

Integers to be preceded by 0

e.g.

08: H = 8 mm

12: H = 12 mm

20: H = 20 mm

25: H = 25 mm

32: H = 32 mm

etc.

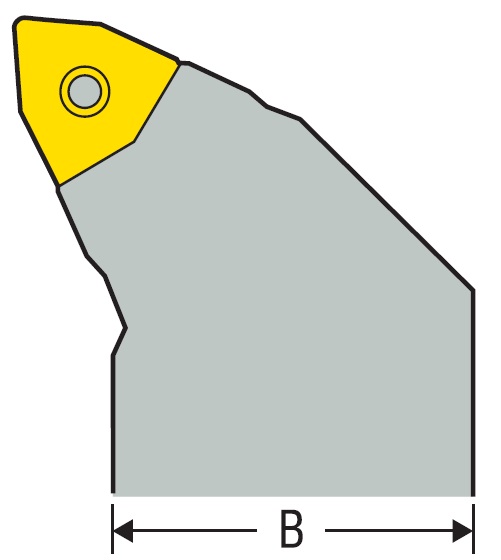

⑦ Shank width

Integers to be preceded by 0

e.g.

08: B = 8 mm

12: B = 12 mm

20: B = 20 mm

25: B = 25 mm

32: B = 32 mm

etc.

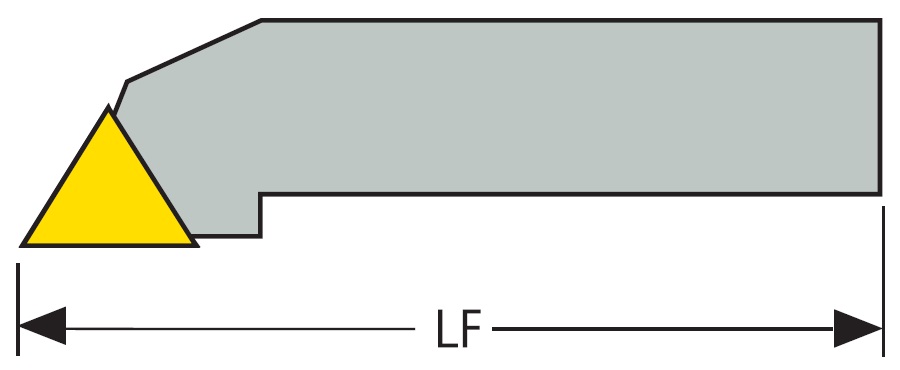

⑧ Tool length

| A = 32 mm | H = 100 mm | Q = 180 mm |

| B = 40 mm | J = 110 mm | R = 200 mm |

| C = 50 mm | K = 125 mm | S = 250 mm |

| D = 60 mm | L = 140 mm | T = 300 mm |

| E = 70 mm | M = 150 mm | U = 350 mm |

| F = 80 mm | N = 160 mm | V = 400 mm |

| G = 80 mm | P = 170 mm | W = 400 mm |

| X = Special |

⑨ Cutting edge length

⑩ Manufacturer’s option

When required a supplementary symbol of letters may be added to the ISO code, separated by a dash, e.g. W for wedge design.